Business

Software development

In automated assembly systems market, widely-recognized our expertise and workmanship lead us continued business growth.

Our continued R&D efforts focus on how we quickly and fully address your ever-changing requirements.

Adapting to emerging and newly invented technologies enable us to materialize process innovation ambitions.

Custom software development for customer requirements

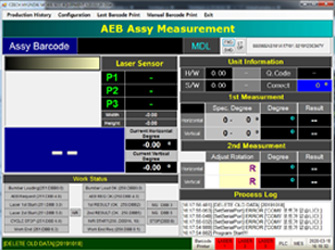

| SCC angle measurement and automated angle control system | - Horizontal and vertical angle measurement using three laser sensors - SCC/AEB product specification verification - Automated correction of horizontal and vertical angles using N/R |

|---|---|

| MD measurement system | - Measurement of retainer MD and clutch case to be assembled - Selection of an ideal shim according to elevation difference |

| Stanley N/R 36-axis tightening torque and static torque data collection program | - Saving torque data incl. N/R torque/angle on network - Collection and retrieving of tightening graph data |

| Induction hardening measurement system | - Recording, retrieving and analysis of induction hardening process dataset including input, output, current, voltage, power and impedance |

| Spark plug gap measurement system | - System designed to identify defective products by estimating properly ‘firing’ voltage after allowing 3,000-4,000 Vdc flows through a spark plug |

| Cell trimming system | - Vision system designed to trim fuel cells by identifying anode & cathode and measuring electrode angles |

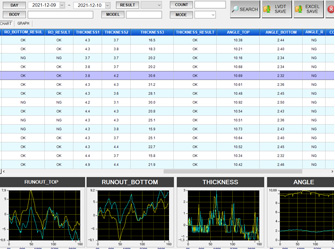

| Runout, disk thickness and angle measurement system | - Disk surface runout measurement using contact and non-contact sensors - Disk thickness and disk displacement measurement |

| Rear axle tone wheel sensor measurement system | - System designed to obtain SPD, TPD and DUTY values from wheel speed sensors attached to a disk during rotation |

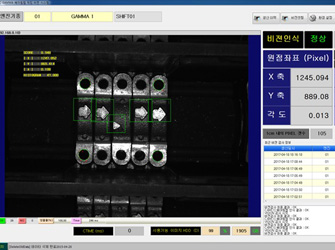

| Vision system for cam cap bolts and letters identification | - Vision system designed to detect cam cap letters and missing mounted bolts |

| Vision system for bearing cap orientation and picking operation monitoring | - Vision system designed to identify type, orientation and location bearing caps and lada frames |

-

AEB SCC angle measurement and automated correction system

AEB SCC angle measurement and automated correction system

-

Axle MD measurement system

Axle MD measurement system

-

Stanley – NR torque data collection program

Stanley – NR torque data collection program

-

Nu engine spark plug

Nu engine spark plug

-

Cell trimming

Cell trimming

-

Runout thickness and angle measurement

Runout thickness and angle measurement

-

Gama cam cap vision system

Gama cam cap vision system

-

Lambda bearing cap picking system

Lambda bearing cap picking system